Cutting out the trailing edges was fairly straightforward, then it came time to add the flaps. I am not going to describe this, since a picture is worth a thousand words, many of which would appear here. Suffice it to say, as long as flap openings are straight and clean and the metal is folded precisely and the cyano has had time to dry, there should be no problem. Common sense, really.

I assembled the landing gear entirely and allowed it to dry thoroughly before adding the etched parts. Earlier I had fitted the landing gear bay's interior. This is more work here than at first you might think - it needs to be well thought out in advance, and following the given instructions is not always the answer.

I also widened the gear nacelle so I could slot the be-metalled gear assembly through it after attaching it to the wing. I had to think at this point about what to add and leave off, with regard to painting.

Fitting the Belcher Bits resin engine cowlings was comparatively easy, particularly the outer cowlings - fit here is almost perfect. The inner cowlings took a lot more work, since the kit's engine nacelles were oversize. There is no doubt these parts add considerably to the overall look of the model; the panel lines, catches and radiators are beautifully rendered, and it was well worth a bit of extra trouble to fit them.

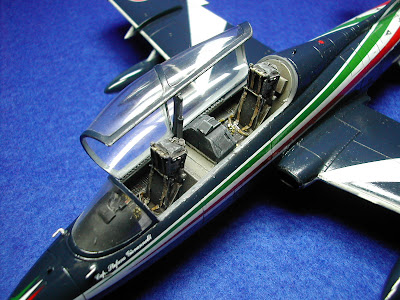

Check out the photos. They'll give you a good idea of what I've been on about. Much more to come on this long term project. Stay tuned!